War on Christmas Lights from Donald Delmar Davis on Vimeo.

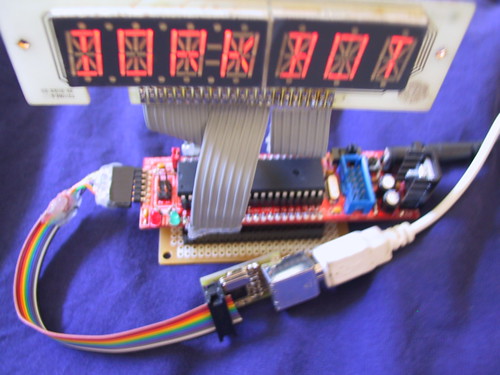

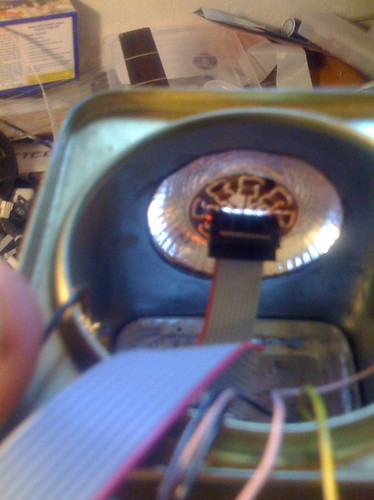

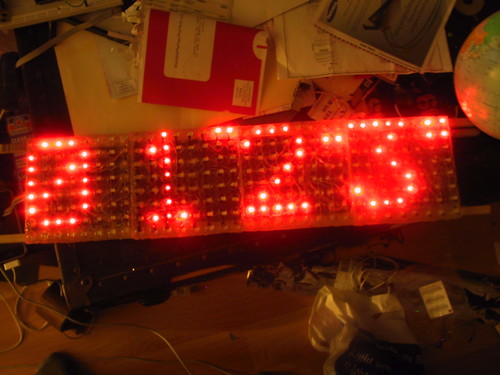

Last year I cast a series of led arrays for thing-a-day but hadnt wired them up. With this in mind I ordered some hc595s in the last group order but the snow canceled the meeting.

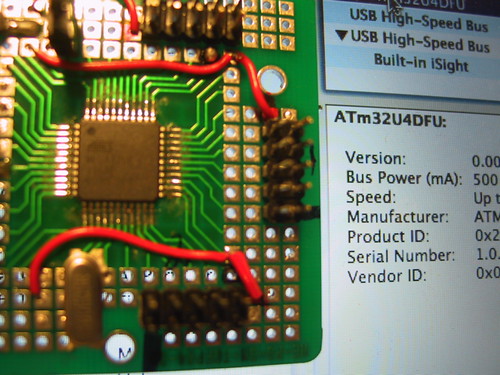

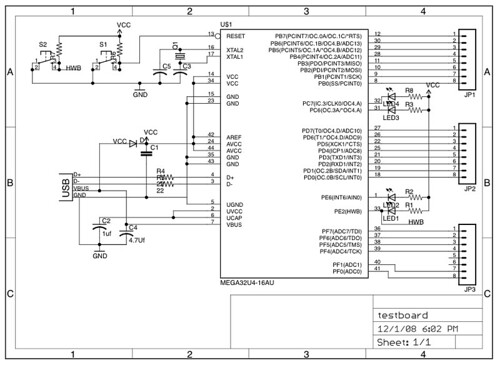

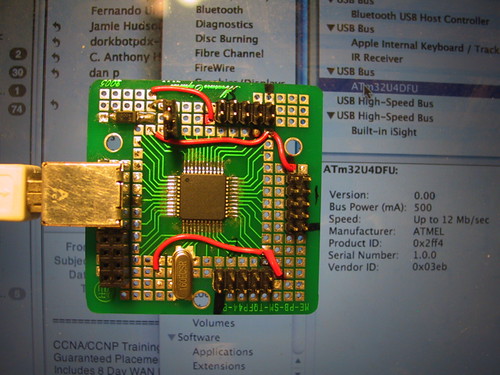

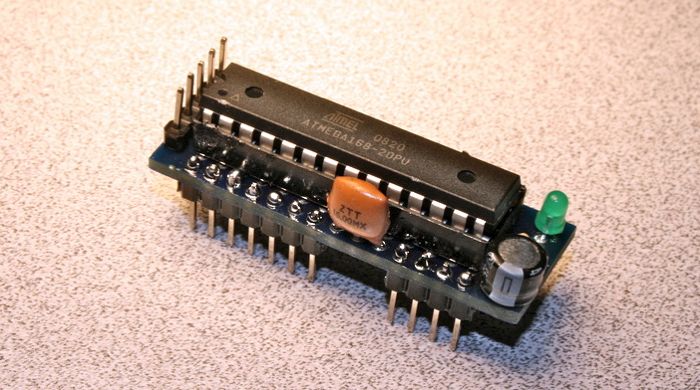

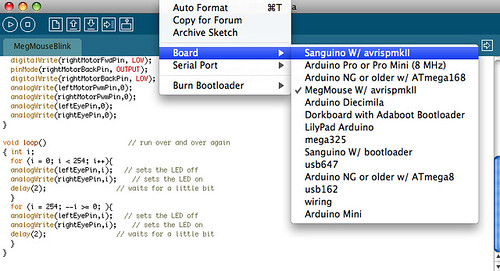

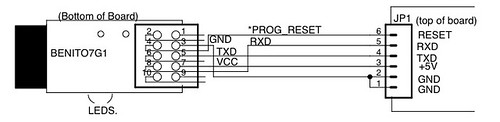

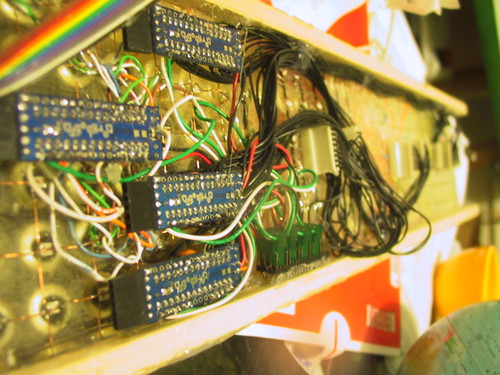

I have been thinking about using the avr to drive the arrays directly and control them using i2c. I hacked 4 dorkboards by cutting the traces for pins 5-12 on the top of the board and soldering 220 ohm resistors on the other side. This gives a one chip solution which does not require a constant refresh or other attention.

/*

Simple 4 node array of leds (8x8).

*/

#include <Wire.h>

int node=0; /* CHANGE THIS BASED ON POSITION OF ARRAY */

volatile int twi_group_offset=128;

volatile int colpins[]={//12,11,10,9,8,7,6,5};

5,6,7,8,9,10,11,12};

volatile int rowpins[]={

17,16,15,14,13,4,3,2};

//2,3,4,13,14,15,16,17};

volatile unsigned long int myTics;

unsigned char pixels[]={0x3E, 0x51, 0x49, 0x45, 0x3E,0,0,node,

0x00, 0x42, 0x7F, 0x40, 0x00,0,1,1,

0x42, 0x61, 0x51, 0x49, 0x46,0,2,2,

0x21, 0x41, 0x45, 0x4B, 0x31,0,3,3

};

void setup() // run once, when the sketch starts

{

int i;

myTics=millis();

for(i=0;i<8;i++){

pinMode(rowpins[i],OUTPUT);

digitalWrite(rowpins[i],LOW);

pinMode(colpins[i],OUTPUT);

digitalWrite(colpins[i],HIGH);

} // sets the digital pin as output

if (node==0) {

Wire.begin();

Serial.begin(19200);

updateSlaveNodes();

} else {

Wire.begin(node+twi_group_offset);

Wire.onReceive(updatePixels); // register event

}

}

void loop() //move most of this into a timer loop.

{

int r,c;

int lastcolpin=colpins[0];

for (c=0;c<8;c++){

lastcolpin=colpins[c];

for(r=0;r<8;r++){

if ((pixels[c]>>r)&0x01){

//if ((!r)||((7-c)==r)||(c==r)){

digitalWrite(rowpins[r], HIGH);

} else {

digitalWrite(rowpins[r], LOW);

}

}

digitalWrite(colpins[c], LOW);

if (node==0) {

updateSlaveNodes();

} else {

//delayMicroseconds(1500); //

delay(3);

}

digitalWrite(lastcolpin, HIGH);

}

}

void updateSlaveNodes() {

int slavenode, row, pixel8;

pixel8=8;

for (slavenode=1;slavenode<4;slavenode++){

Wire.beginTransmission(slavenode+twi_group_offset);

for (row=0;row<8;row++) {

Wire.send(pixels[pixel8++]);

}

Wire.endTransmission();

};

}

// function that executes whenever data is received from master

// this function is registered as an event, see setup()

void updatePixels(int howMany)

{ int r=0;

while(Wire.available()) //

{

pixels[r++] = Wire.receive(); // receive byte as a character

}

}

The next step is to move the actual refresh into a timer routine so that the body of code for the main node can focus on content.

/*------------------------------------------------------------ xmas timer array

*

* This is the program for a 4x8x8 led display using a processor for each segment

* To program the different nodes set the node variable below. Node 0 is the

* master node which keeps the pixel memory for the remaining nodes.

*

* The master node takes its memory and sends updates to each of the other segments

* via the i2c buss using the Wire library.

*

* Each node takes its 8byte array of data and strobes it onto the display using

* the 8 bit timer2 overflow interrupt.

*

* The first 7 characters are loaded into the display memory using the

* loadCharacters function. The array is then shifted to the left in the main loop

* with the next character being loaded a collumn at a time.

*

* The character data and the bitmap for the 5x7 array are stored in program

* memory.

*

* Since interrupts are used all of the globals are marked as volatile.

*

* CopyLeft 2008 Donald Delmar Davis, Tempus Dictum, Inc.

* This is free software (GPL)

*/

#include <Wire.h>

#include <avr/interrupt.h>

#include <avr/io.h>

#include <avr/pgmspace.h>

#define FREEK 180

int node=0; /* CHANGE THIS BASED ON POSITION OF ARRAY */

unsigned char PROGMEM Font5x7[] = {

0x00, 0x00, 0x00, 0x00, 0x00,// (space)

0x00, 0x00, 0x5F, 0x00, 0x00,// !

0x00, 0x07, 0x00, 0x07, 0x00,// "

0x14, 0x7F, 0x14, 0x7F, 0x14,// #

0x24, 0x2A, 0x7F, 0x2A, 0x12,// $

0x23, 0x13, 0x08, 0x64, 0x62,// %

0x36, 0x49, 0x55, 0x22, 0x50,// &

0x00, 0x05, 0x03, 0x00, 0x00,// '

0x00, 0x1C, 0x22, 0x41, 0x00,// (

0x00, 0x41, 0x22, 0x1C, 0x00,// )

0x08, 0x2A, 0x1C, 0x2A, 0x08,// *

0x08, 0x08, 0x3E, 0x08, 0x08,// +

0x00, 0x50, 0x30, 0x00, 0x00,// ,

0x08, 0x08, 0x08, 0x08, 0x08,// -

0x00, 0x60, 0x60, 0x00, 0x00,// .

0x20, 0x10, 0x08, 0x04, 0x02,// /

0x3E, 0x51, 0x49, 0x45, 0x3E,// 0

0x00, 0x42, 0x7F, 0x40, 0x00,// 1

0x42, 0x61, 0x51, 0x49, 0x46,// 2

0x21, 0x41, 0x45, 0x4B, 0x31,// 3

0x18, 0x14, 0x12, 0x7F, 0x10,// 4

0x27, 0x45, 0x45, 0x45, 0x39,// 5

0x3C, 0x4A, 0x49, 0x49, 0x30,// 6

0x01, 0x71, 0x09, 0x05, 0x03,// 7

0x36, 0x49, 0x49, 0x49, 0x36,// 8

0x06, 0x49, 0x49, 0x29, 0x1E,// 9

0x00, 0x36, 0x36, 0x00, 0x00,// :

0x00, 0x56, 0x36, 0x00, 0x00,// ;

0x00, 0x08, 0x14, 0x22, 0x41,// <

0x14, 0x14, 0x14, 0x14, 0x14,// =

0x41, 0x22, 0x14, 0x08, 0x00,// >

0x02, 0x01, 0x51, 0x09, 0x06,//

0x32, 0x49, 0x79, 0x41, 0x3E,// @

0x7E, 0x11, 0x11, 0x11, 0x7E,// A

0x7F, 0x49, 0x49, 0x49, 0x36,// B

0x3E, 0x41, 0x41, 0x41, 0x22,// C

0x7F, 0x41, 0x41, 0x22, 0x1C,// D

0x7F, 0x49, 0x49, 0x49, 0x41,// E

0x7F, 0x09, 0x09, 0x01, 0x01,// F

0x3E, 0x41, 0x41, 0x51, 0x32,// G

0x7F, 0x08, 0x08, 0x08, 0x7F,// H

0x00, 0x41, 0x7F, 0x41, 0x00,// I

0x20, 0x40, 0x41, 0x3F, 0x01,// J

0x7F, 0x08, 0x14, 0x22, 0x41,// K

0x7F, 0x40, 0x40, 0x40, 0x40,// L

0x7F, 0x02, 0x04, 0x02, 0x7F,// M

0x7F, 0x04, 0x08, 0x10, 0x7F,// N

0x3E, 0x41, 0x41, 0x41, 0x3E,// O

0x7F, 0x09, 0x09, 0x09, 0x06,// P

0x3E, 0x41, 0x51, 0x21, 0x5E,// Q

0x7F, 0x09, 0x19, 0x29, 0x46,// R

0x46, 0x49, 0x49, 0x49, 0x31,// S

0x01, 0x01, 0x7F, 0x01, 0x01,// T

0x3F, 0x40, 0x40, 0x40, 0x3F,// U

0x1F, 0x20, 0x40, 0x20, 0x1F,// V

0x7F, 0x20, 0x18, 0x20, 0x7F,// W

0x63, 0x14, 0x08, 0x14, 0x63,// X

0x03, 0x04, 0x78, 0x04, 0x03,// Y

0x61, 0x51, 0x49, 0x45, 0x43,// Z

0x00, 0x00, 0x7F, 0x41, 0x41,// [

0x02, 0x04, 0x08, 0x10, 0x20,// "\"

0x41, 0x41, 0x7F, 0x00, 0x00,// ]

0x04, 0x02, 0x01, 0x02, 0x04,// ^

0x40, 0x40, 0x40, 0x40, 0x40,// _

0x00, 0x01, 0x02, 0x04, 0x00,// `

0x20, 0x54, 0x54, 0x54, 0x78,// a

0x7F, 0x48, 0x44, 0x44, 0x38,// b

0x38, 0x44, 0x44, 0x44, 0x20,// c

0x38, 0x44, 0x44, 0x48, 0x7F,// d

0x38, 0x54, 0x54, 0x54, 0x18,// e

0x08, 0x7E, 0x09, 0x01, 0x02,// f

0x08, 0x14, 0x54, 0x54, 0x3C,// g

0x7F, 0x08, 0x04, 0x04, 0x78,// h

0x00, 0x44, 0x7D, 0x40, 0x00,// i

0x20, 0x40, 0x44, 0x3D, 0x00,// j

0x00, 0x7F, 0x10, 0x28, 0x44,// k

0x00, 0x41, 0x7F, 0x40, 0x00,// l

0x7C, 0x04, 0x18, 0x04, 0x78,// m

0x7C, 0x08, 0x04, 0x04, 0x78,// n

0x38, 0x44, 0x44, 0x44, 0x38,// o

0x7C, 0x14, 0x14, 0x14, 0x08,// p

0x08, 0x14, 0x14, 0x18, 0x7C,// q

0x7C, 0x08, 0x04, 0x04, 0x08,// r

0x48, 0x54, 0x54, 0x54, 0x20,// s

0x04, 0x3F, 0x44, 0x40, 0x20,// t

0x3C, 0x40, 0x40, 0x20, 0x7C,// u

0x1C, 0x20, 0x40, 0x20, 0x1C,// v

0x3C, 0x40, 0x30, 0x40, 0x3C,// w

0x44, 0x28, 0x10, 0x28, 0x44,// x

0x0C, 0x50, 0x50, 0x50, 0x3C,// y

0x44, 0x64, 0x54, 0x4C, 0x44,// z

0x00, 0x08, 0x36, 0x41, 0x00,// {

0x00, 0x00, 0x7F, 0x00, 0x00,// |

0x00, 0x41, 0x36, 0x08, 0x00,// }

0x08, 0x08, 0x2A, 0x1C, 0x08,// ->

0x08, 0x1C, 0x2A, 0x08, 0x08 // <-

};

unsigned char PROGMEM banner[] = "Happy Holidays!!! Merry Christmas!!! May every man with \"Merry Christmas\" on his lips be boiled in his own blood pudding with a steak of holly driven through his heart! Christmas! BAH! HUMBUG!!!";

volatile int twi_group_offset=128;

volatile int colpins[]={5,6,7,8,9,10,11,12};

volatile int rowpins[]={17,16,15,14,13,4,3,2};

volatile unsigned long int myTics; //counter for timer interrupt.

volatile unsigned char pixels[]={

0x3E, 0x51, 0x49, 0x45, 0x3E,0,0,node,

0x00, 0x42, 0x7F, 0x40, 0x00,0,0,1,

0x42, 0x61, 0x51, 0x49, 0x46,0,0,2,

0x21, 0x41, 0x45, 0x4B, 0x31,0,0,3,

0x00, 0x00, 0x00, 0x00, 0,0,0,0}; //pixel buffer rounded out to another 8 bytes

volatile unsigned int cursorpos=0;

volatile unsigned int charcursor=0;

volatile unsigned int currentcol;

volatile unsigned int charmod;

volatile unsigned char currentchar;

volatile unsigned int currentcharoffset;

/*---------------------------------------------------------------------setup()

* initialize timer2

* setup the i/o pins (initialized with everything off);

* Initialize the i2c buss;

* if master node then load initial characters into display.

*/

void setup() // run once, when the sketch starts

{

int i;

currentcol=0;

/*------------ setting up timer two. ----------------*/

TCCR2A = 0; // normal mode

TCCR2B = 1<<CS22 | 1<<CS21 | 0<<CS20; // clock selection

TIMSK2 |= 1<<TOIE2; // enable overflow interupt

TCNT2=FREEK; // adjustment of period

ASSR=0; // paranoid

myTics=0; // counter for delays

sei(); // enable interrupts

for(i=0;i<8;i++){

pinMode(rowpins[i],OUTPUT);

digitalWrite(rowpins[i],LOW);

pinMode(colpins[i],OUTPUT);

digitalWrite(colpins[i],HIGH);

}

if (node==0) { // master node

Wire.begin();

Serial.begin(19200);

loadCharacters();

updateSlaveNodes();

} else {

Wire.begin(node+twi_group_offset);

Wire.onReceive(updatePixels); // register event

}

}

/*------------------------------------------------------------ISR(TIMER2_OVF_vect)

* loads the next collumn into the led array

*

*/

ISR(TIMER2_OVF_vect) {

int r;

digitalWrite(colpins[currentcol], HIGH); //turn off the last column.

if (++currentcol > 7) {

currentcol=0;

}

for(r=0;r<8;r++){

if ((pixels[currentcol]>>r)&0x01){

digitalWrite(rowpins[r], HIGH);

} else {

digitalWrite(rowpins[r], LOW);

}

}

digitalWrite(colpins[currentcol], LOW);

myTics++;

TCNT2 = FREEK;

};

/*--------------------------------------------------------------loadCharacters()

* load the initial characters into the pixel buffer

*/

void loadCharacters(){

int ch,i,j;

cursorpos=0;

for (charcursor=0;charcursor<7;charcursor++) {

ch=pgm_read_byte_near(banner+charcursor);

j= (ch-32) & 0x000000ff;

j = j*5;

for (charmod=0;charmod<5;charmod++){

pixels[cursorpos++]=pgm_read_byte_near(Font5x7+j+charmod);

}

}

}

/*------------------------------------------------------------updateSlaveNodes()

* send the pixel data to the slave nodes.

*/

void updateSlaveNodes() {

int slavenode, row, pixel8;

if (node==0) {

pixel8=8;

for (slavenode=1;slavenode<4;slavenode++){

Wire.beginTransmission(slavenode+twi_group_offset);

for (row=0;row<8;row++) {

Wire.send(pixels[pixel8++]);

}

Wire.endTransmission();

};

}

}

/*------------------------------------------------------------------udatePixels()

* recieve the pixel data from the master node.

* executes whenever data is received from master

* this function is registered as an event, see setup()

*/

void updatePixels(int ignored)

{ int r=0;

while(Wire.available()) //

{

pixels[r++] = Wire.receive(); // receive byte as a character

}

}

/*-------------------------------------------------------------------------loop()

*

*/

void loop()

{int c;

//int head=pixels[0];

updateSlaveNodes();

for (c=1;c<35;c++) {

pixels[c-1]=pixels[c];

}

if (charmod==5) {//get next char

charcursor++;

charmod=0;

currentchar=pgm_read_byte_near(banner+charcursor);

if (currentchar=='\0'){

currentchar=pgm_read_byte_near(banner);

charcursor=0;

}

currentcharoffset = (currentchar-32) & 0x000000ff;

currentcharoffset = currentcharoffset*5;

}

pixels[34]=pgm_read_byte_near(Font5x7+currentcharoffset+charmod);

charmod++;

while (myTics<90) ; myTics=0L; //wait a few hundred millisecconds

}